Architect’s Guide to Rainscreen vs. Face-sealed Wall Assemblies

Introduction:

Are you an architect seeking to optimize your building assembly design? Understanding the differences between rainscreen and face-sealed wall assemblies is essential. This comprehensive guide will delve into the benefits, considerations, and best practices for both types of exterior wall assemblies to ensure your project's success. Let's explore how you can create a structurally sound and efficient building envelope.

Section 1: Rainscreen Wall Assemblies

1.1 What is a Rainscreen?

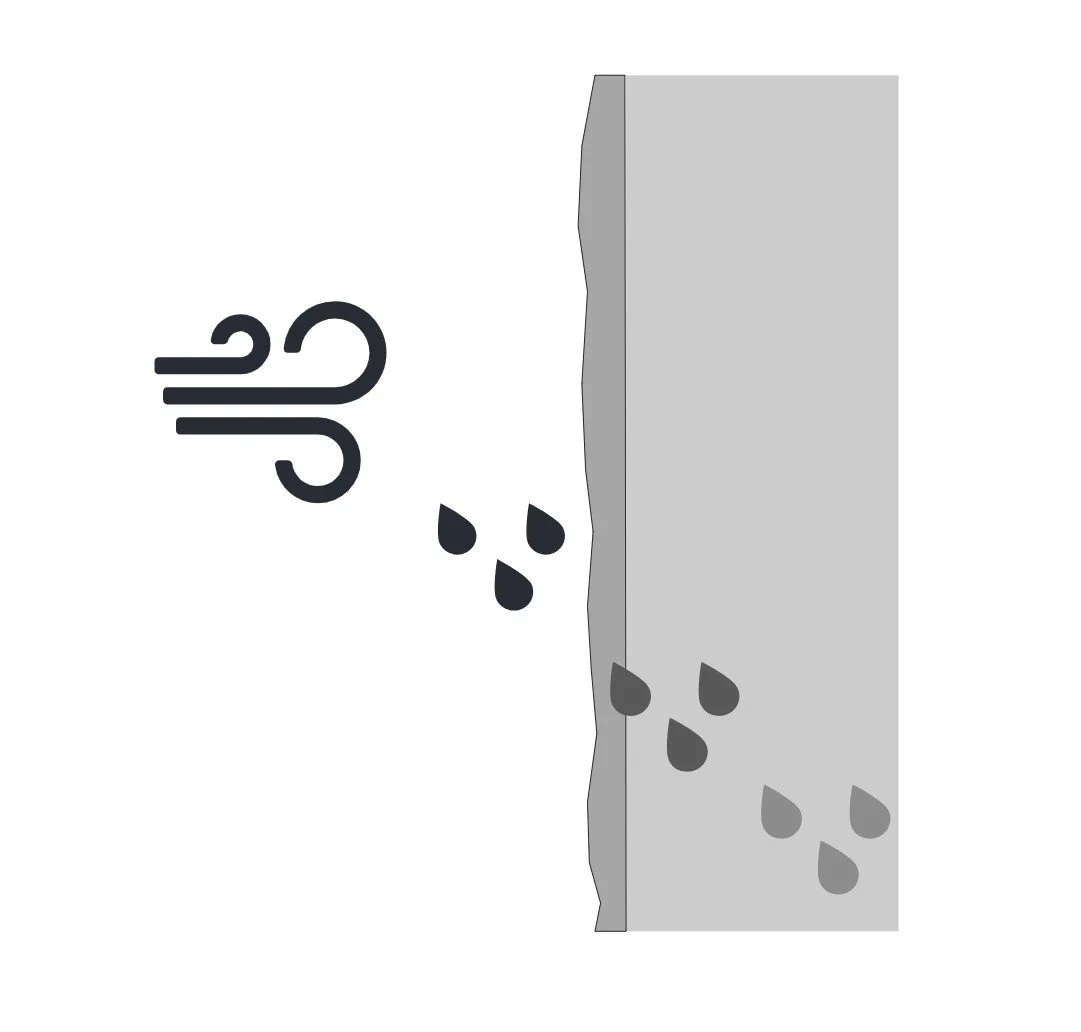

A Rainscreen is a type of exterior wall assembly that separates the finish layer from the moisture prevention and thermal layer using airspace. This is achieved by using a specific sub-framing system or conventional furring methods with metal or wood for the sub-framing. The sub-framing provides a continuous air layer behind the finish for ventilation and drainage.

1.2 Key Considerations for Rainscreen System

When constructing a building, it's crucial to think about all the areas where water might enter or exit and make sure to install flashing to guide the water away from the structure. If water gets trapped in the rainscreen system, it defeats the purpose of having one and can lead to damage. It's essential to remove any water from the assembly to maintain the system’s effectiveness.

When creating a Rain screen, it's crucial to safeguard everything behind the finish from infiltration by Air, Water, and Vapor into the building assembly. The performance of the products and installation techniques you choose will determine the overall effectiveness of the Rain screen. It's essential to seek advice from manufacturers for product suggestions that are tailored to your project and rain screen system based on the climate zone.

1.3 Educational Resources for Rainscreen Systems

To access more educational resources, consider visiting reputable organizations. You may want to start with RAiNA (Rainscreen Association of North America) for educational content on Rainscreen systems. You can find their website at https://rainscreenassociation.org/. Another option is the Metal Construction Association (MCA), which provides educational content on metal construction. You can find their website at https://www.metalconstruction.org/.

Section 2: Face-sealed Wall Assemblies

If you're designing face-sealed wall assemblies, there are specific guidelines you should follow to ensure they're both structurally sound and functioning correctly.

2.1 Selecting Suitable Materials

When constructing a wall assembly, it is vital to use appropriate materials for their intended purpose and comply with local building codes and regulations. Key factors to consider include durability, insulation, and resistance to moisture and fire. Commonly used materials for face-sealed systems include Wood, Composite, Vinyl, Metal, PVC, GWB, and Stucco.

2.2 Ensuring Proper Ventilation as well as Flashing and Drainage details

To prevent the buildup of mold and mildew, it's essential to ensure proper ventilation in face-sealed wall assemblies. This can be achieved by incorporating ventilation channels and ensuring the correct detailing for adequate airflow.

It is crucial to have proper flashing and drainage details to ensure that water is diverted away from the wall assembly. Be sure to identify the appropriate materials for flashing and detailing for penetrations and transitions in the wall assembly.

2.3 Adhering to Industry Best Practices

For many years, face-sealed wall assemblies have been commonly utilized in construction. Consequently, industry standards and best practices have been established to ensure their appropriate installation and design. It's important to consult with industry professionals and refer to relevant codes and standards. By following these guidelines, you can ensure that your design meets the best practices and industry standards.

Conclusion:

As an architect, understanding the differences between rainscreen and face-sealed wall assemblies empowers you to create durable, efficient, and code-compliant building envelopes. Whether you choose a rainscreen system with its unique sub-framing and ventilation benefits or opt for a face-sealed design following established best practices, this guide equips you with the knowledge to maximize your building assembly design's potential.

By implementing the principles outlined in this guide, you can confidently deliver sustainable, high-performance projects that stand the test of time. Stay ahead in the world of architecture by mastering the art of building assembly design with the proper knowledge and expertise.

Written by D.TO: Design TOgether

Empower your daily practice