When it comes to incorporating natural stone cladding into building designs, selecting the right anchor system is crucial. Stone anchor systems provide the necessary support, durability, and resistance to external forces, ensuring the safety and long-term performance of the cladding. In this comprehensive guide, we will explore the key considerations and types of anchor systems to help architects design effective and reliable stone cladding assemblies.

1. Understanding Stone Anchor Systems:

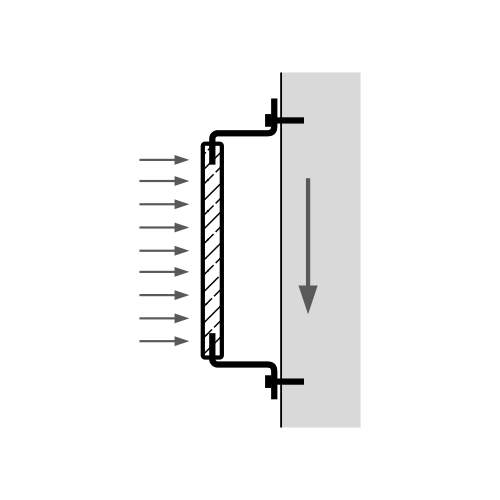

Stone anchor systems play a crucial role in securing stone cladding to building structures. They support gravity loads and resist lateral forces such as wind pressure, thermal movement, and seismic activity. The system has three critical load transition points: stone-to-anchor junction, anchor itself, and anchor-to-building frame connection.

2. Types of Stone Anchors:

Clip or Shelf Angle Anchors: Clip or shelf angle anchors use L-shaped metal clips to support the stone’s dead load. The vertical leg is attached to the building frame, while the horizontal leg supports the stone cladding. Shelf angles are typically made of mild steel with corrosion-resistant coatings.

Aluminum Extrusions: Aluminum extrusions are another option for restraining both gravity and lateral loads. These can be either short sections or continuous sections.

Strap Anchors: Strap anchors are flat metal bars that are inserted into a kerf (slot) in the stone panel. They transfer the load from the stone to the wall and must be strong enough to hold the load without losing its form.

Plug Anchors: Plug anchors consist of a threaded rod screwed into a tapped plug inserted into a round hole in the stone. They are especially suitable for softer stone types like sandstone and provide strong anchorage

3. Material Considerations:

To avoid corrosion, it is crucial to regulate the contact between the minerals in the stone and the metal of the anchor. Different stone types vary in their susceptibility to corrosion, so factors such as climate, environment, and stone mineralogy should be considered.

4. Anchorage System Fill and Finish Work:

It’s important to consider the joints and spaces between stone panels and adjacent components to allow for movement. In order to weatherproof joints and act as a buffer between cladding elements, sealants can be used. There are various types of fillers to choose from, including cementitious fillers, resinous fillers (such as epoxy), and elastomeric fillers (like silicone and polyurethane sealants). It’s worth noting that gypsum-based fillers are not recommended.

5. Shims:

Shims are physical spacers that offer extra support. They can be crafted from stainless steel or high-density, high-impact plastic and should withstand the load without any deformation.

6. Collaboration and Early Communication:

To ensure a proper design, selection, and installation of the stone anchor system, it is crucial to communicate early on with a facade consultant, structural engineer, and stone installer. Collaboration among these professionals is essential.

It is of utmost importance to create natural stone cladding anchor systems that are effective and safe for building assemblies. Architects should consider various factors, such as load forces, stone type, climate, and environmental conditions, to make informed decisions when choosing or designing anchor systems. Collaborating with industry professionals early on guarantees a successful integration of stone cladding into building designs. By following the guidelines provided in this comprehensive guide, architects can excel in natural stone cladding design and construction.