As architects, ensuring effective insulation and moisture control in below-grade perimeter design is crucial. In this blog post, we provide essential design guidance for below-grade perimeter insulation. By considering the factors discussed here, architects can create efficient and long-lasting insulation systems that minimize heat loss and condensation while maximizing performance.

When it comes to below-grade perimeter insulation, architects have two primary options: vertical insulation on the interior or exterior of a stem wall or horizontal insulation under the slab or to the exterior below the finish grade. Interior vertical insulation is limited by the depth of the footing or as prescribed by code for the project’s climate zone whichever is less, while underslab insulation offers more flexibility. It is as at minimum as prescribed by code for the projects climate zone, but you may choose to insulate the entire floor if desired. When run to the exterior it must be installed at minimum 12” (305 mm) below finish grade. Discuss with your building enclosure consultant which method of insulating is appropriate for your project.

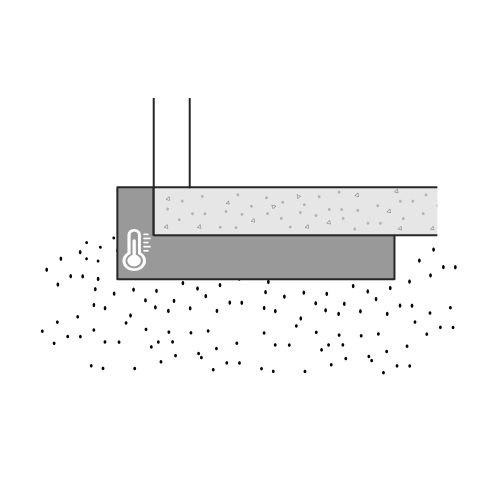

Condensation control and thermal continuity is an essential consideration when placing insulation inside the foundation wall or under the slab. It is important to insulate the joint between the slab and the foundation wall to prevent heat transfer through the thermal bridge at the slab edge. The insulation can range from 1” to 2” (25-50mm) in thickness at this point – coordinate slab design with the Structural Engineer of Record.

When using insulation on the exterior side of the substructure, ensure that you are using an insulation type that is for below-grade use. Typically, three insulation products are used below grade: extruded polystyrene (XPS), expanded polystyrene (EPS), and rigid mineral fiber panels. Extruded polystyrene (nominal R-5 per inch) is a common choice. Expanded polystyrene (nominal R-4 per inch) is less expensive but has a lower insulating value. EPS used below-grade can be at risk for performance reduction if exposed to moisture, which may reduce the effective R-value. This potential reduction must be accounted for when selecting the amount and type of insulation to be used.

To ensure the utmost effectiveness of below-grade perimeter insulation, it is imperative to seal all joints and gaps thoroughly. Pay special attention there are no gaps in insulation joints – all joints are to be tight fitting. Coordinate how insulation is secured in place with abutting construction materials.

By considering these factors, architects can design and implement highly effective and efficient below-grade perimeter insulation systems. By optimizing insulation and moisture control, architects can create sustainable and high-performance buildings that stand the test of time. Let us strive together to unlock the potential of below-grade perimeter insulation and foster excellence in architectural design.

Ready to streamline your below-grade perimeter insulation detailing into your design?

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!