Did you know that building materials undergo high stress at various building transitions?

In the dynamic world of architecture and building design, managing the stress caused by environmental and structural factors is crucial. Deflection joints, also known as movement joints, play a pivotal role in accommodating the movements of building components due to temperature fluctuations, moisture, settling, and more. This blog post explores the critical function of deflection joints in preventing structural damage and maintaining stability across various building transitions.

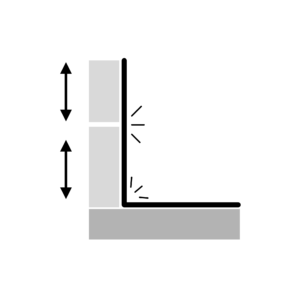

Deflection joints, also known as movement joints, are important features in building construction that allows for the movement of building components caused by temperature changes, moisture, building settlement, and other factors. The purpose of these joints is to prevent structural damage and ensure the building remains stable when undergoing this stress.

The need for deflection joints depends on various factors such as the size and height of the building, climate conditions, type of construction materials, and expected movement. Design together with your structural engineer as they review the building design and determine the appropriate location and spacing of deflection joints.

Deflection joints need to be able to accommodate both expansion and contraction. Each type of joint serves a specific purpose, and the selection must be based on the building design and expected movement. The location and spacing of deflection joints must be determined based on the building design and the expected movement of building components. The size of the deflection joint must be based on the expected movement and the type of joint.

The materials used for deflection joints must be compatible with the building components and the expected movement. Common materials used for deflection joints include neoprene, silicone, polyurethane, and butyl rubber.

Deflection joints are indispensable in modern construction, ensuring buildings can adapt to natural shifts without compromising structural integrity. By understanding the key factors influencing their design, such as building size, material behavior, and environmental conditions, architects and engineers can effectively integrate these joints into their projects. Proper selection, sizing, and material choice for deflection joints not only prevent potential damage but also enhance the overall resilience and safety of the structure.