Did you know that many AWRB changes in building assemblies require particular transitions for moisture control? Most AWRB systems require a transition strip or transition membrane at all changes in substrate and geometry. This includes shifts from sheathing to concrete, sheathing to steel, transitions around openings, the roof, the foundation, and more.

Ideal transition membranes must be made of materials compatible with all interfacing substrates.

AWRB materials typically can only bridge a gap up to 0.125 inches. Any gaps exceeding this must be supported—typically by a compatible sealant, backer rod, wood blocking, sheet metal, or another AWRB manufacturer–approved substrate.

Silicone Transition Strips or membranes can be used where building movement occurs. These provide:

A flexible transition

Continuous AWRB performance

Accommodation for structural movement

Silicone Transition Strips are recommended at all curtain wall transitions, where the membrane is typically set into the glazing pocket.

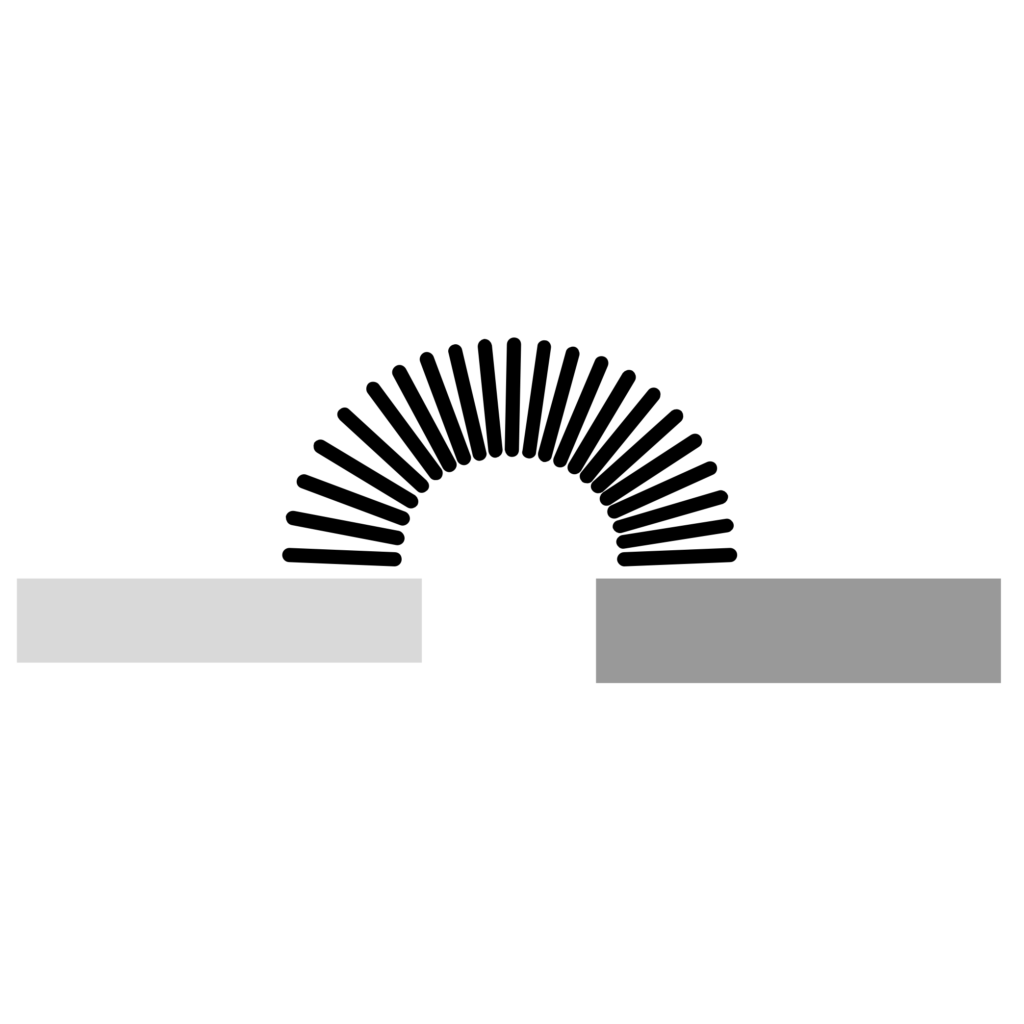

Transition strips can be installed to connect different materials and construction types to maintain a continuous AWRB.

Design TOgether with product manufacturers and façade consultants to select suitable transition strip assemblies that align with your project’s AWRB products and performance requirements.

By following these guidelines, you can ensure that transition strip detailing supports proper moisture control and maintains a continuous AWRB across substrate changes.

In summary, selecting the right transition strip and coordinating with manufacturers ensures durable, movement-tolerant, and code-aligned envelope performance.

Ready to streamline your Transition Strip Assembly detailing into your design?

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!