Architectural details are where design becomes real. They translate intent into instructions the field can trust, and they determine how well a building performs long after occupancy. This guide reframes architectural detailing as a craft and a system, one that balances creativity, building science, and coordination, so your projects read clearly and build cleanly.

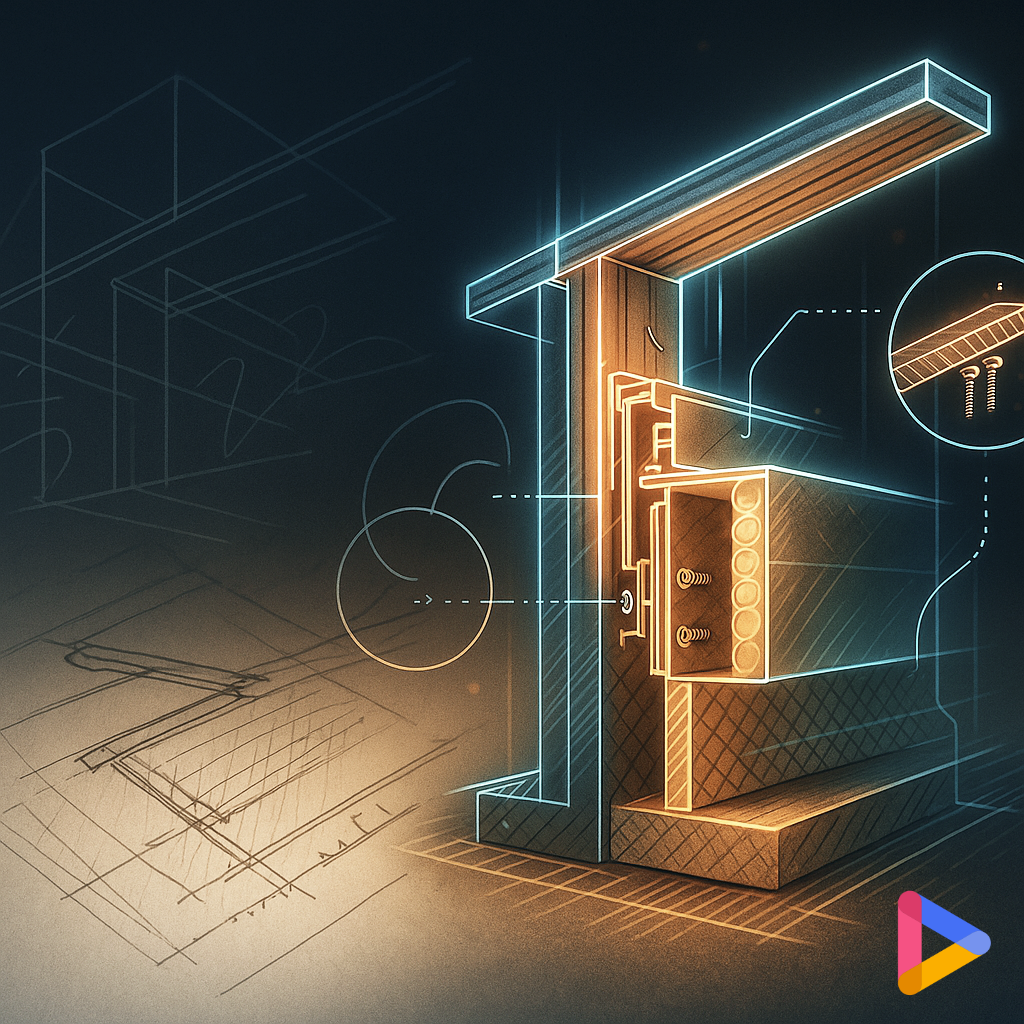

Every design decision culminates at a junction, the architectural detail, where materials meet, control layers continue, and intent becomes constructible form. When details are clear, crews don’t guess, performance holds, and buildings age well. When they’re vague, field improvisation takes over, and quality drifts, resulting in endless RFIs, schedule delays, cost overruns, and sometimes unfortunate litigation.

Details shape outcomes across the building enclosure and interior systems.

These are just a few examples, and there is much more to explore.

Excellence in detailing is the hallmark of mature practice because it marries imagination with physics. Modern tools can support this judgment, but great detailing always begins with understanding how materials behave and how assemblies come together in real construction environments.

Constructible detailing begins with material behavior, tolerances, and realistic sequencing. Great details anticipate the way trades actually perform the work, not the idealized moment frozen in a section cut.

Align the detail with the real sequence of work. What is primed, what is lapped, what is sealed, and in what order.

Clarity beats complexity. Favor one repeatable pattern over five clever variations that confuse reviewers and installers. Establish a clear graphic hierarchy: start with assemblies, followed by fasteners and tolerances, and finally references, so the reader can grasp the meaning effortlessly. As projects grow in complexity, maintaining this level of clarity across dozens of details and revisions becomes less about individual skill and more about having systems that preserve intent as conditions change.

At transitions, make continuity visible. If you can’t trace air, water, thermal, and vapor layers continuously without lifting your pen, the detail is not finished. A constructible detail anticipates how trades sequence their work in actual site conditions, not the theoretically perfect version.

Use the model as the database and the sheet as the explanation. Embed architectural details directly into assemblies and component families where they add value, such as backsets, thermal breaks, edge distances, anchor geometry, and parameterized size, so tags and schedules inherit truth from the model.

Manage annotation standards and view templates so any placed view reflects your office standard on the first try. Intelligent detail components make detailing efficient.

These are just a few examples and there is much more to explore:

Model what drives coordination and overlay 2D for sequence and tolerances. Unlike general BIM documentation workflows, detail-level BIM must strike a balance. Model what matters, and avoid 2D sketches that contradict modeled reality. When detail intelligence lives with the assembly, not in disconnected notes, teams spend less time chasing coordination and more time refining design.

Inconsistent scales, uncoordinated references, and misplaced callouts waste review cycles and cause field errors. “Detail drift” occurs when library standards don’t match project-specific conditions.

A detail drawn for a temperate climate may fail in a freeze–thaw zone unless joint widths and drainage paths adjust. Good detailing is not static. It adapts to context. Most of these failures aren’t design mistakes. They’re information management failures in which decisions made once aren’t consistently carried forward.

A reliable detail library multiplies team quality and consistency. Centralize only the details you trust, and retire confusing or redundant variants.

But the goal is not storage but deployment. The library should behave like an operational platform, not an archive, in which details are easy to find, easy to insert, and kept in sync everywhere they appear.

Make the library searchable, teachable, and proactive. Designers shouldn’t dig through a giant folder. The workflow should suggest relevant details as context emerges (assembly type, climate tag, fire rating, substrate), so designers spend less time searching and more time refining.

Version control keeps improvements propagating across projects, ensuring that lessons learned once don’t have to be relearned on every job. Stamp details with version and change notes (“added end dam,” “updated sealant type,” “increased joint width for movement”). Modern libraries can embed metadata directly inside detail files so schedules, tags, and specifications update consistently.

A good detail library behaves like software with small updates, frequent releases, and a visible history. Libraries scale best when detail intelligence, such as performance data, spec alignment, and change history, is embedded and validated automatically, not maintained by hand or hunted in folders. That’s how you turn detailing knowledge into a repeatable advantage across the whole firm.

Details that stand alone invite contradiction. A constructible detail aligns with the matching specification section, the basis-of-design product, and the performance claims that reviewers and installers rely on.

Stable naming is non-negotiable. One detail tag must map to one schedule row and one specification section. When details and specs echo the same values, submittal cycles shrink, and field improvisation nearly disappears.

Over time, these callouts increase predictability and reduce callbacks. When this linkage is enforced systematically, consistency becomes the default rather than something teams have to remember to check.

If these checks rely entirely on manual review, they won’t scale reliably across larger teams or tighter schedules.

Ready to streamline your BIM workflow?

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!