Insulated metal panels (IMPs) are a roofing solution characterized by lightweight sandwich panels. Comprising an exterior and interior metal skin with an insulating foam core, IMPs provide a versatile and efficient design option for many building types. The exterior substrates are often specified as G90 galvanized steel or AZ50 aluminum-zinc coated steel for painted IMPs, and AZ55 aluminum-zinc for unpainted panels, ensuring durability.

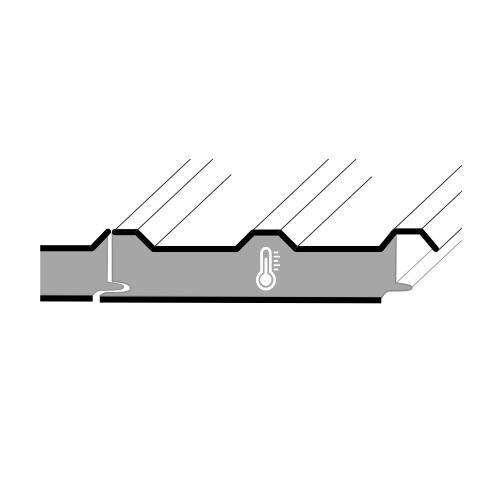

IMPs consist of metal skins with an insulating foam core. The interior-facing surface can be finished with a light-reflective polyester coating. Foam is injected or poured between the sheets, expanding, curing, and bonding to fill the cavity completely. This process creates continuous thermal performance across the roofing assembly.

The combination of metal skins, insulation, and embedded side joint sealant forms multiple control layers. An insulated metal panel serves as a water-control layer, air-control layer, and vapor-control system. The exterior surface is UV-resistant and durable, while the thermal control layer is placed inboard.

IMPs are suitable for all climate zones—cold, hot, humid, dry, mixed, and marine. Their insulating properties, continuous insulation at transitions, high spanning capability, and rapid installation make them practical for a variety of projects.

Provide insulation and weather control in one system

High spanning capabilities with rapid installation

Suitable for both low- and steep-slope roofs in commercial and residential projects

Achieve weather-tightness, with some systems rated Class A for fire resistance

Integrate with other wall and roof systems while maintaining control-layer continuity

IMPs can be tailored to meet project-specific requirements. Options include insulation values, span lengths, and load/span capabilities. This flexibility allows architects to design insulated metal panel roofing systems that align precisely with performance goals.

Always Design TOgether with your building envelope consultant and product manufacturers when specifying insulated metal panels. Collaboration ensures that the chosen roofing system meets project requirements while achieving performance, compliance, and durability.

An insulated metal panel system provides architects with a durable, energy-efficient, and adaptable roofing solution. By addressing control layers, spanning capacity, and customization, IMPs can be optimized for long-term building performance. Close collaboration with consultants and manufacturers ensures seamless integration into roofing design.

Ready to streamline your insulated metal panel detailing into your design?

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!