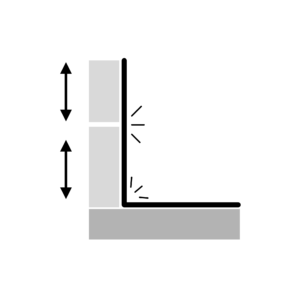

Did you know that building materials undergo high stress at various transition points? Deflection joints, also known as movement joints, are essential components in construction that allow structural elements to expand, contract, and shift due to temperature changes, moisture variation, or settlement.

The primary purpose of deflection joints is to prevent cracking or structural damage while maintaining the building’s integrity and performance under stress.

The inclusion of deflection joints in a building depends on several factors:

Building size and height — larger structures require more joints to accommodate movement.

Climate conditions — temperature swings increase expansion and contraction.

Construction materials — each material reacts differently to stress.

Expected movement — structural analysis helps predict displacement ranges.

Collaborate closely with your structural engineer to determine the optimal location and spacing of deflection joints during early design stages.

Deflection joints must accommodate both expansion and contraction. Each joint type serves a specific function, and selection depends on the building’s design and expected movement.

Location and spacing: Determined by the structural configuration and magnitude of anticipated movement.

Joint size: Based on the extent of movement and the type of joint.

Compatibility: Materials and profiles should match the adjoining building components.

The materials used for deflection joints must be compatible with adjacent elements and capable of withstanding cyclical movement. Commonly used materials include:

Neoprene: Offers flexibility and weather resistance.

Silicone: Ideal for sealing and accommodating wide joint movement.

Polyurethane: Durable with excellent adhesion to multiple substrates.

Butyl rubber: Effective in resisting moisture and maintaining elasticity over time.

Selecting the correct material ensures long-term performance and prevents water intrusion or joint failure.

Successful deflection joint design requires a balance between movement accommodation and durability. Engage structural engineers and envelope consultants early to analyze environmental and structural factors influencing joint placement and dimensioning. Well-designed deflection joints minimize stress concentration, extend building lifespan, and maintain façade performance.

Ready to streamline Deflection Joints detailing into your design?

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!