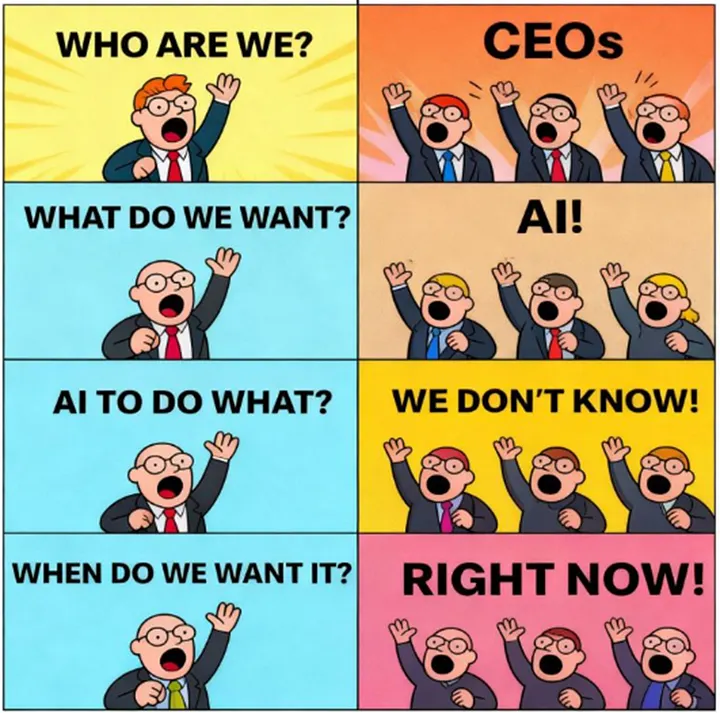

Image: “What Do We Want?” meme (creator unknown), via ExampleSite — https://www.linkedin.com/posts/nikhai-jaysen-224429143_artificialintelligence-aitransformation-activity-7375789882851430400-08U_/, accessed 10/15, 2025. Used for commentary.

In AEC, chasing the latest AI tool without a clear problem and ROI target leads to disappointment. Start with a specific pain point, define a measurable outcome, then pick the simplest solution that solves it, AI or not. Treat implementation friction as the work, not a blocker.

If you work in architecture, engineering, and construction (AEC), the AI wave is crashing into your day‑to‑day. The hype is loud, the pressure is real, and everyone seems to be “adopting AI.” As a CTO of a SaaS company, I’ve felt it too. I’ve clicked the “X is dead” and “Y just changed the game” LinkedIn posts, tried shiny tools with big promises , and watched most trials fizzle out.

I’m not anti‑AI. If anything, I believe it will get more powerful sooner than most expect. My problem was clear: I chased technology without a clear problem or targeted ROI. I was hoping AI would dramatically change how my team works. It didn’t… because hope isn’t a plan.

What I actually needed was a solution. Whether it’s AI‑powered or not, the bar is the same: it must reduce a real pain in a way I can measure.

This isn’t just personal experience. Recent research suggests most GenAI pilots stall out because organizations avoid the messy process changes that create value. One widely cited MIT study reports that about 95% of enterprise GenAI pilots fail to show measurable business impact, largely due to sidestepping the organizational friction needed to make them work. The message isn’t “AI is broken”, it’s “process matters.” Forbes

And separate research points to the same root cause: workflow redesign is the strongest driver of AI’s bottom‑line impact. In other words, value shows up when we rewire how the work gets done, not when we just add a model on top. McKinsey & Company

Meanwhile in AEC, adoption is climbing, but so are the contradictions. A recent industry survey found ~74% of AEC firms are using AI in at least one project phase, yet 72% still rely on paper documents for parts of their process. That delta is exactly what “friction” looks like in the field. Engineering.com

If you’ve felt that “try everything, gain nothing” loop, you’re not alone. The way out isn’t more features; it’s changing how our daily practice actually works in AEC. So let’s get practical: bind one workflow to one metric, make the objectives explicit, and measure what improves. Below is the smallest, repeatable sequence that’s moved our KPI in real projects.

“We need to cut construction documentation time by 30% within 90 days without increasing headcount.”

Swap in your pain: finding references, drawing QA/QC process, schedule risk, distributing internal knowledge, and etc.

Train, rewrite a checklist, tweak handoffs, adjust permissions. This is the value‑creation step most pilots skip. If it doesn’t change how someone works on Tuesday, it won’t change your KPI by Friday. (Again: workflow redesign is where EBIT impact comes from.) McKinsey & Company

Quick ROI sketch (illustrative):

30 staff × 5 hrs/week × 12 weeks = 1,800 hrs baseline.

–40% = 720 hrs saved. At $100/hr loaded, that’s $72,000 in labor value.

If the pilot costs $26,000, net benefit is $46,000 (≈ 1.77× ROI).

Scale up only when you can show this math on one slide.

A deeper dive on why “friction” (data cleanup, SOPs, permissioning, training) is the work , and how to budget and sequence it so your pilot doesn’t become shelfware. I’ll also unpack the MIT “95%” conversation and how to make sure you land in the 5% that do move the needle. Forbes

Notes / Sources

Discover how D.TO enhances your daily design workflows on D.TO’s key features page, or schedule a demo to explore them in more detail!!

Written by Juhun Lee, CTO & Co-Founder of D.TO: Design TOgether